Apple Sauce Triathlon

Cook. Chop. Chill. Repeat. (For eight hours)

Above (left to right): Janice Pastor, Seth Rolland, Kathy Darrow, and Suzanne Wilson with happy smiles at the end of a long day.

What do you do on a sunny October Sunday? When given apples, PT Gleaners make applesauce. A huge thank you to Katie Appleyard, Bobi Beery, Kathy Darrow, Mike Farrell, Mary Hunt, Stacey Larsen, Jim Moore, Janice Pastor, Tom Pendley, Seth Rolland, Doug Van Allen, and Suzanne Wilson. An additional thank you to David Engle for use of his compressor.

The herculean effort produced 1700 pounds of sauce: 1590 pounds of sauce (212 gallons) to be used in Port Townsend and Chimacum school lunches; some of it will also end up at the Food Banks and the Recovery Café.

Arriving at 7:30 am at the Blue Heron Middle School kitchen dock, the volunteer crew unloaded 4 truckloads of apples that were hand picked by gleaners over the past couple of weeks. As fast as they were unloaded, the chopping, cooking, and chilling stations were set up. The crew was encouraged to try their hands at all stations to cross-train as well as give themselves a break from repetitive tasks. Taking breaks became even more important as the day unfolded -- it was the biggest amount of apples sauced, ever. In prior years the saucing took place over many weekends, but this time due to a less abundant crop and the need, it was decided to tackle the harvest all in one day.

By the numbers:

They started with 3265 total pounds of apples picked and hand sorted.

2755 pounds were chopped, cooked, and chilled into sauce

380 pounds were taken to Chimacum schools for cider

130 pounds were held for the Gleaner Cider Party on Oct. 30

The remaining poundage either didn't make the cut or was what was created when the stems, skins, and seeds were removed from the sauce

The result: 1700 pounds or 224 gallons.

CHOP

Apples were first sorted by hand and divided between saucing or cider making at Chimacum schools and the Gleaner party. (Bad apples went directly into the bin for composting.) Saucing apples were then washed and run through the chipper into a 5 gallon pail where they were carried to the kitchen.

COOK

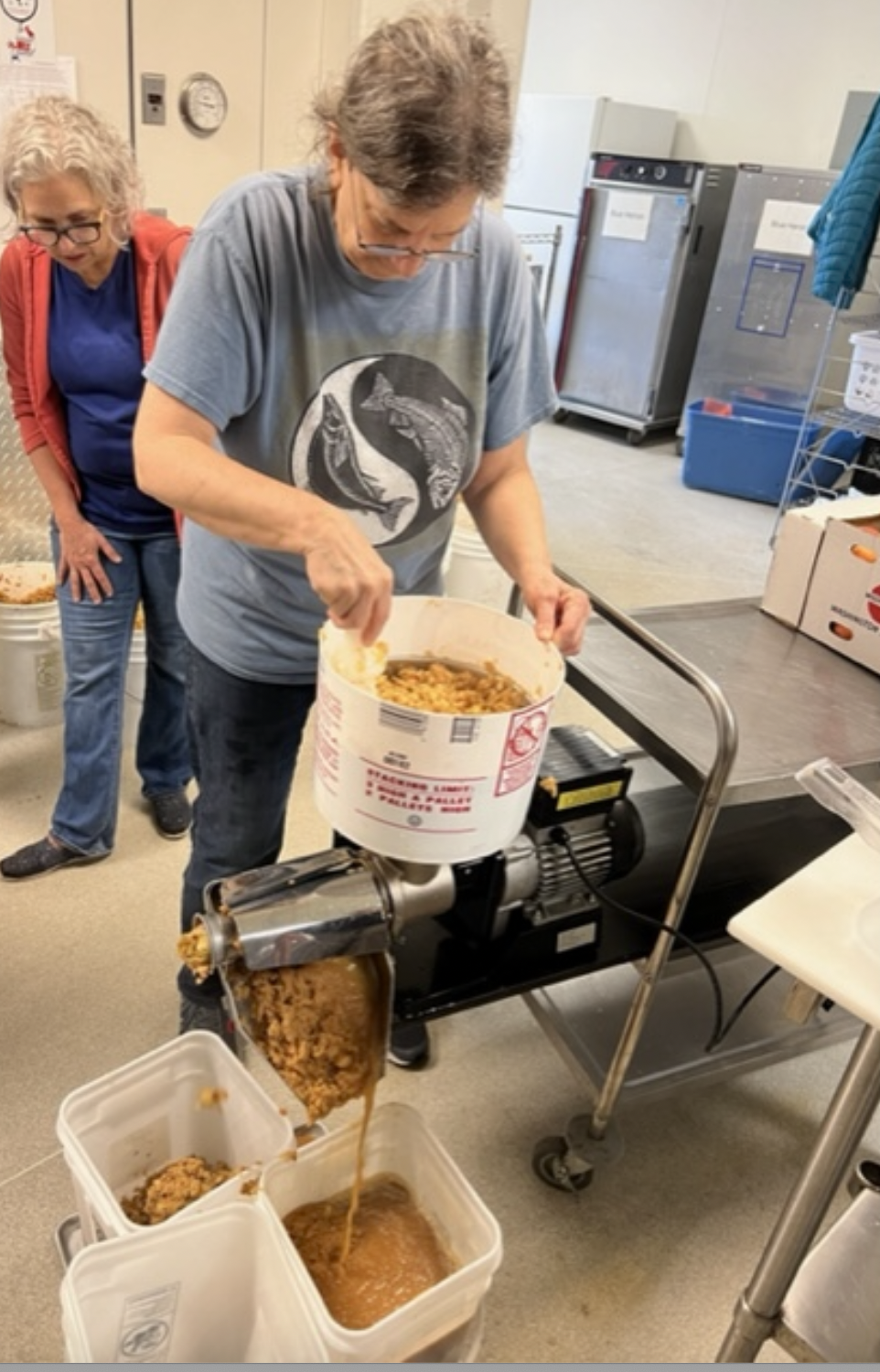

Seven pails of chopped up apples went into the big steam kettle. (Five pails into the smaller steam kettle.) When the mash reached 180 degrees, the steam lid was clamped down to boil them for five more minutes. Fully cooked mash was then carefully poured into "Fabio" the Italian sauce maker machine one pitcher full at a time. At that point the hot mash was pushed through a screen separating all the seeds, skins, and stems out -- sending the cleaned sauce in one container and the roughage into another.

CHILL

In order for the sauce to cool before going into the freezer for keeps, the sauce was run through water cooled pipes to bring the temperature down. It's no small task as apple sauce is very thick and doesn't like to give up its heat, but the killer chiller machine does the trick by running the sauce through metal pipes surrounded with larger pipes holding cold water. The heat transfers to the metal and then the water and the now cooled sauce is ready to go into the freezer for the final big chill.

It's not a simple process, or fast, but it is efficient and an example of what can be accomplished when one person wondered, "How can we use the excess of apples growing in our backyards?"